which energy conversion takes place when a solar cell is used to light a street lamp?

How Solar Panels Work A solar cell is a device that responds to light and converts light energy into electricity. There are many kinds of materials that can produce photovoltaic effects, such as: monocrystalline silicon, polycrystalline silicon, amorphous silicon, gallium arsenide, selenium indium copper, etc. Their power generation principles are basically the same.

Now, crystalline silicon is used as an example to describe the photovoltaic power generation process.

P-type crystalline silicon is doped with phosphorus to obtain N-type silicon, forming a P-N junction. When light irradiates the surface of the solar cell, part of the photons is absorbed by the silicon material; the energy of the photons is transferred to the silicon atoms, causing the electrons to transition and become free electrons that gather on both sides of the P-N junction to form a potential difference.

When the external circuit is turned on , under the action of this voltage, there will be current flowing through the external circuit to produce a certain output power. The essence of this process is: the process of converting photon energy into electrical energy.

conversion of light energy to electrical energy

Solar panels are not light energy – chemical energy – electrical energy, but directly convert solar energy into electrical energy.

When sunlight hits a solar cell, a photovoltage is generated, which is the photovoltaic effect. If a load is connected to both ends of the solar cell at this time, photocurrent will be generated, thus generating electrical energy. Solar power generation is called photovoltaic power generation.

Photovoltaic (PV or photovoltaic) is the abbreviation of solar photovoltaic power system. It is a new type of power generation system that utilizes the photovoltaic effect of solar cell semiconductor materials to directly convert solar radiation energy into electrical energy.

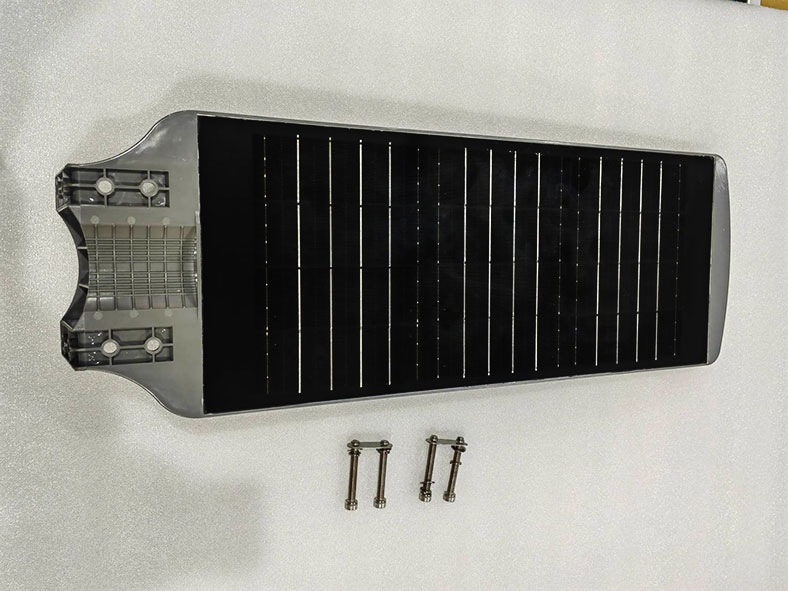

Solar power generation is divided into photothermal power generation and photovoltaic power generation. Solar power generation usually refers to solar photovoltaic power generation, referred to as “photovoltaic”. The photovoltaic power generation system consists of three major parts: solar panels (components), controllers and inverters. They are mainly composed of electronic components and do not involve mechanical parts. Therefore, the power generation equipment is extremely refined, reliable, stable, and has a long life.

It is easy to install and maintain. Easy. Compared with commonly used thermal power generation systems, in addition to no pollution emissions, solar power generation systems also have the advantages of a short construction period and the use of building roofs.

Photovoltaic lighting is lighting using solar power generation systems. Independent photovoltaic lighting systems generally use batteries as energy storage devices to store the electrical energy output by solar cells during the day and provide power to lighting loads at night. Such independent photovoltaic lighting systems have high practical value in remote areas, deserts, border outposts and other areas that are not covered by power grids.

Solar cells are the input power supply of photovoltaic lighting systems, providing the electrical energy required for lighting and control of the entire system. Under daytime lighting conditions, the solar cell converts the received light energy into electrical energy, and charges the battery through the charging circuit; after dark, the solar cell stops working, the output end is open, and the battery converts the stored chemical energy into electrical energy and outputs it to the lighting load.

The power supply of the intelligent controller is supplied by the battery. The selection and coordination of the capacity of each part of the system requires comprehensive consideration of cost, efficiency and reliability. Solar cells are the most expensive part of the entire system, and their capacity selection affects the cost of the entire system. In comparison, batteries are relatively cheap, so you can choose a battery with a larger capacity to make full use of the power generated by the solar cell. In addition, when coordinating with the lighting load, continuous cloudy conditions should be taken into consideration and a certain margin should be left for the system capacity.

light-heat-electricity conversion

The light-heat-electricity conversion method generates electricity by utilizing the thermal energy generated by solar radiation. Generally, a solar collector converts the absorbed thermal energy into steam as a working fluid, and then drives a steam turbine to generate electricity. The former process is a light-heat conversion process; the latter process is a heat-electricity conversion process, which is the same as ordinary thermal power generation.

The disadvantages of solar thermal power generation are low efficiency and high cost. It is estimated that its investment is at least 5 to 10 times more expensive than ordinary thermal power plants. A 1000MW solar thermal power station requires an investment of 2.0 to 2.5 billion US dollars, and the average investment for 1 kW is 2000 to 2500 US dollars. Therefore, it is suitable for small-scale special occasions, but large-scale utilization is economically uneconomical and cannot compete with ordinary thermal power plants or nuclear power plants.

Conversion efficiency of solar panels and definition of conversion efficiency

Abstractly speaking: conversion efficiency is the percentage of the output power of the battery to the incident light power!

Specifically: the battery is irradiated with sunlight of a certain power density. After the battery absorbs photons, it will excite the material to generate carriers. The carriers that contribute to the performance of the battery will eventually be collected by the electrodes. Naturally, the collection will be accompanied by current. , voltage characteristics, that is, corresponding to an output power, then dividing the generated power by the power of the incident light is the conversion efficiency!

theoretical formula

Efficiency = (open circuit voltage * short circuit current * filling factor) / incident light power density = battery output power density / incident light power density

Factors affecting solar energy conversion rate

Solar light intensity

A solar cell is a device that converts sunlight into electricity. Under normal circumstances (note the conditions), the efficiency of a solar cell increases as the light intensity increases. Furthermore, the efficiency of solar cells is related to the comprehensive climate conditions of the installation site.

Battery materials

Different materials have different light absorption coefficients, different bandgaps, different quantum efficiencies, and different battery efficiencies. Generally speaking, the light coefficient of monocrystalline silicon/polycrystalline silicon is much smaller than that of amorphous silicon, so the thickness of amorphous silicon solar cells is only one percent of the thickness of monocrystalline silicon/polycrystalline silicon to better absorb sunlight. In addition, theoretically speaking, the ultimate efficiency of GaAs solar cells is greater than that of other solar cells, because the bandgap width of GaAs solar cells is 1.4ev, which is closest to the maximum value of the spectrum energy of terrestrial sunlight.

Craftsmanship

Different process levels naturally lead to different battery efficiencies. If you look at each factory, you will understand why the raw materials are almost the same, but the efficiency of the batteries produced is very different. This is the reason. The level of technology naturally has an important relationship with the level of equipment. Generally speaking, the more advanced the equipment, the better the technology, and the higher the battery efficiency. (Technology is the product of equipment. Without equipment, technology cannot be realized, it is just a fantasy).

How to calculate the conversion rate of solar panels? The conversion efficiency of solar panels is determined based on illumination and light efficiency. The conversion efficiency of solar panels with different components is also different. Currently, solar panels are mostly divided into polycrystalline silicon and monocrystalline silicon.

The order of silicon production is: silica ore–>industrial silicon–>polycrystalline silicon–>monocrystalline silicon. Monocrystalline silicon is made from polycrystalline silicon drawn in a single crystal furnace. Monocrystalline silicon can also be produced by zone melting. However, the dislocation density of zone melted single crystal silicon is relatively large. Therefore, semiconductor devices mostly use drawn single crystal silicon as the raw material.

Monocrystalline silicon cells have high cell conversion efficiency and good stability, but the cost is high. Polycrystalline silicon cells are low in cost, but their conversion efficiency is slightly lower than monocrystalline silicon solar cells.

When light resources are sufficient, the light conversion efficiency of polycrystalline silicon is 6%-10%, and the light conversion efficiency of monocrystalline silicon is more than 15%.

First test the output voltage and current of the solar panel under test under standard light intensity:

1. Standard light intensity refers to: AM1.5, 1000W/square meter, component temperature: 25 degrees. It is best to use a special solar photovoltaic tester for testing.

2. Parameters to test: Pw, Vop, Iop, Voc, Isc.

3. Divide the power of the solar panel by the area of the solar panel and then divide by 1000 to get the efficiency.

Assumption: The power of the solar panel is 5W, the area is: 0.03 square meters,

Then its efficiency is: 5/0.03/1000=0.167=16.7%;

That is to say, it converts 16.7% of the 1000W sunlight energy per square meter into electrical energy.

Author

ZGSM Solar

We are a professional solar street light manufacturer with a 20-year history.